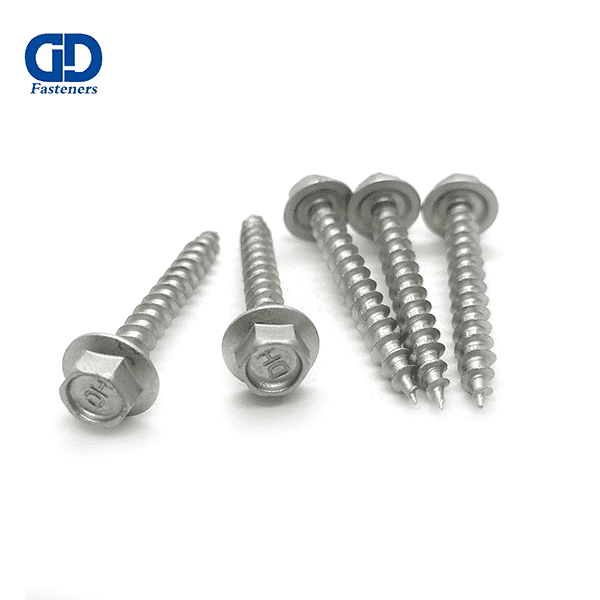

Stainless Steel Stud Bolts

| Description | |

| Brand | DD Fasteners |

| FOB Price | $ 0.01~$ 0.08/piece |

| Payment Terms | T/T |

| Material | Stainless Steel |

| Surface Treatment | Plain |

| Grade | A2/A4 |

| Specification | M13-M70 |

| Supply ability | |

| Supply ability | 5000tons/ per month |

| OEM Service | Yes |

| Min.Order Quantity | 1Ton/ Tons |

| Ppackaging& Delivery | |

| Packaging Details | Bags/ Boxes / pallet |

Basic Information

Normal Sizes: M13-M70

Material: Carbon Steel, Stainless Steel

Surface Treatment:Plain, HDG ,Zinc, Teflon

Brief Introduction

Stud bolts are threaded rods with hexagonal heads on both ends, designed to be used with nuts for fastening two components together. They are commonly employed in construction and industrial applications, providing a sturdy and reliable means of joining materials. Stud bolts are versatile and come in various materials and sizes to accommodate different project requirements.

Functions

Stud bolts serve several essential functions in various applications:

Fastening Components: The primary function of stud bolts is to fasten two components together. The threaded design allows for a secure connection when used with nuts.

Load Distribution: Stud bolts help distribute loads evenly across connected components. This is crucial for maintaining structural integrity and preventing localized stress points.

Easy Installation and Removal: Stud bolts facilitate easier installation and removal of components compared to traditional bolts. The threaded design allows for straightforward assembly and disassembly.

Versatility: Stud bolts are versatile and can be used in diverse industries and applications, including construction, machinery, and automotive, due to their availability in various materials, lengths, and thread sizes.

Space Efficiency: The threaded design of stud bolts allows for a more compact and space-efficient connection compared to bolts with heads, making them suitable for applications with space constraints.

Maintenance and Repairs: Stud bolts simplify maintenance and repair processes by allowing for the replacement of components without the need to disassemble an entire structure. This can reduce downtime in industrial settings.

Temperature and Corrosion Resistance: Depending on the material used, stud bolts can offer resistance to high temperatures, corrosion, and other environmental factors, enhancing their durability in challenging conditions.

Advantages

Stud bolts offer several advantages in various applications:

Ease of Installation: Stud bolts simplify the installation process, especially in confined spaces, as they can be threaded through components without the need for access to both ends.

Assembly and Disassembly: Stud bolts allow for easier assembly and disassembly of components, making maintenance and repairs more efficient without the need to completely dismantle a structure.

Load Distribution: The threaded design of stud bolts helps distribute loads evenly across connected components, reducing the risk of localized stress concentrations.

Space Efficiency: Stud bolts provide a more space-efficient solution compared to bolts with heads, making them suitable for applications where space is limited.

Versatility: Available in various materials, lengths, and thread sizes, stud bolts are versatile and can be adapted to different project requirements and environmental conditions.

Temperature Resistance: Depending on the material used, stud bolts can offer resistance to high temperatures, making them suitable for applications in environments with elevated heat.

Corrosion Resistance: Stud bolts made from corrosion-resistant materials are effective in environments where exposure to moisture or corrosive substances is a concern, increasing their durability.

Reduced Downtime: In industrial settings, stud bolts facilitate quicker repairs and replacements, minimizing downtime and improving overall operational efficiency.

Cost-Effective: Stud bolts can be a cost-effective solution due to their ease of installation and maintenance, potentially reducing labor and downtime costs over the long term.

Customization: Stud bolts can be manufactured with specific lengths and thread sizes to meet project requirements, allowing for a customized and precise solution.

Applications

Stud bolts find applications in a variety of industries and scenarios due to their versatility and effectiveness. Some common applications include:

Construction: Used for connecting structural components, such as steel beams and columns, in construction projects.

Petrochemical Industry: Employed in the assembly of pipelines, flanges, and other equipment in the oil and gas sector.

Power Plants: Used to fasten components in power generation facilities, including connections in boilers, turbines, and other machinery.

Heavy Machinery: Stud bolts are integral in assembling components of heavy machinery, providing a secure and reliable connection.

Automotive Industry: Used in the assembly of engines, transmissions, and other automotive components where a strong and stable connection is essential.

Aerospace: Stud bolts are utilized in the aerospace industry for connecting various components in aircraft and spacecraft manufacturing.

Shipbuilding: In ship construction, stud bolts are used for fastening structural elements, equipment, and other components.

Refineries: Stud bolts are crucial in connecting pipes, valves, and flanges in refinery equipment for the processing of chemicals and petrochemicals.

Railroad Industry: Stud bolts play a role in connecting rail components and other infrastructure in the railroad sector.

Mining: Used in the assembly of mining equipment and structures, providing stability in demanding and rugged environments.

Chemical Processing Plants: Stud bolts are employed in assembling components in chemical processing equipment where resistance to corrosive substances is crucial.

Infrastructure Projects: Stud bolts are utilized in various infrastructure projects, including bridges, tunnels, and other civil engineering applications.

Contact us:

Tel: 86 -0310-6716888

Mobile(WhatsApp): 86-13230079551; 86-18932707877

Email: dd@ddfasteners.com